Alpine continued the upgrade offensive at the Formula One race in France with a new underbody – The A522’s “diet” also continues to progress

Alpine is the only team on the grid to have updated its car at every single Formula One race this season. While some of the updates have been minor tweaks and improvements, a well-coordinated development programme has seen the team consistently put together comprehensive upgrade packages, putting them in a good position in the battle for fourth place in the Constructors’ Championship.

While few of its rivals have been able to match the scale of such an overhaul, Alpine says there is no sign of it running out of steam. “Every race there was something new. And that will continue,” promises sporting director Alan Permane. “We will take another small step in Hungary and then we have two proper steps planned at Spa and Zandvoort.”

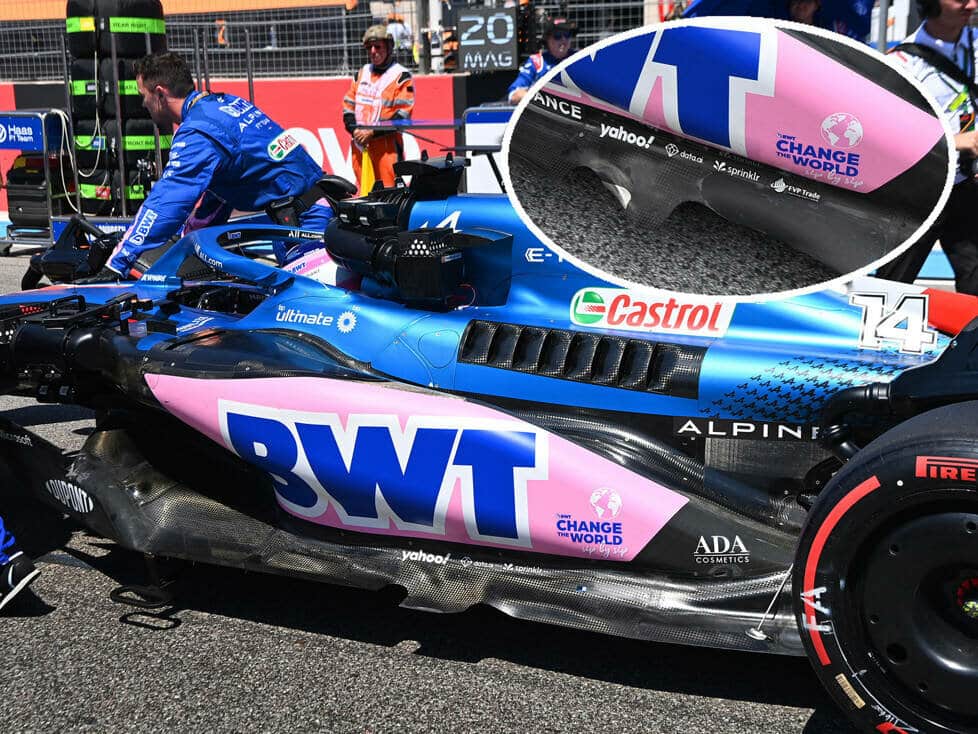

Alpine’s last major innovation concerned the big side box update, which takes further inspiration from their own design team and is inspired by the Red Bull and Ferrari solutions. Last week in France, however, the focus was on the underbody

New underbody with “skate” element

“At Silverstone we unveiled our third underbody this year and this one is an evolution of that,” said Permane. “We call it the MK3B floor. You can’t really see that much from the top, but the detail [centre cut-out] is new. “

The cut-out in the middle of the floor is quite different from the original MK3 specification floor (seen in the first picture), and Red Bull’s influence is clearly visible here too, but the really exciting stuff takes place on the underside of the floor, which we can’t see.

Like Red Bull and Ferrari, who have also adopted this solution, the A522 now has a ‘skate’ element. As you might expect, without pictures of the underside of the floor it’s difficult to show the skate in detail, but this picture gives us a clear view of the outermost tip (red arrow).

Bottoms are reworked in the factory

This picture also shows very well how the floor can be loaded in several directions, as the front part of the floor (in front of the front floor arch) remains at a stable height above the surface of the track, while the rear part is low above the asphalt.

The team was obviously pleased with the feedback from its drivers and the data collected, because although it only had two examples of this version of the underbody available in France, it sent the replacement car back to the factory at Enstone where it was modified.

“I think we had two brand new MK3Bs [in France] and three of the A version,” says Permane. “The A versions go back [to the factory] to be modified. It’s not really a job we can do on the track. It’s quite a complex modification.

The A522 successfully slims down

Another focus of Alpine this season is the “diet plan” to bring the A522 closer to the weight limit. Normally, cars gain weight as the season progresses and new parts are introduced, but Permane explains that the French carmaker has managed to go the other way.

“We are very close [to the weight limit],” he said. “We’re not quite there, but we’re close to the limit, except for a few kilos,” the sporting director said. “It’s really difficult to reduce weight, especially on a completely new car with a new concept.”

“Usually the cars gain three to five kilos over the course of a season when you add upgrades and have to fix something, or you’ve been a bit too aggressive with the material and it’s a bit too light,” said Permane. “I think we’re seven and a half or eight kilos lighter than we were at the start of the season, so that’s really a massive achievement. “

2023 more extreme design solutions?

Alpine still believes that significant progress is possible in the remainder of the season, but is also aware that certain aspects of its current design will reach their limits due to the way the A522 is laid out. Therefore, more extreme solutions are to be expected for 2023.

“We’re still improving the underbody – the floor and the superstructure and things like that,” Permane adds. “I suspect that what we learn this year will inevitably lead to some more extreme examples next year. Where we’re constrained this year by the layout of radiators and exhausts and things like that, obviously that can all be changed next year. “